|

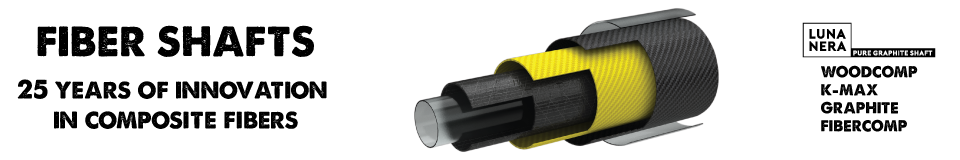

OVIERVIEW ON COMPOSITE SHAFTS

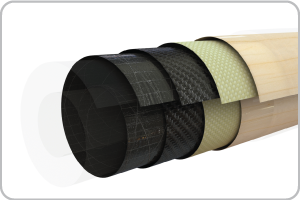

The composite fiber shafts are completely different from the wooden ones. First of all they are not derived from the processing of solid material but they are based on tubes formed by different layers of synthetic fibers. The technical characteristics of the game change from the number and type of layers. In general, a fiber shaft has much more power than a wooden one. This is the reason why it is used for over 25 years for the Italian game were the opponent ball has to run long distances on the table |

|

MATCH YOUR TASTE

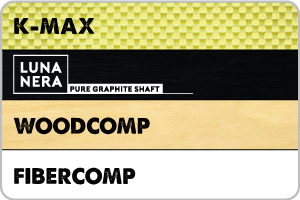

The Longoni Team, currently, suggest 4 types of synthetic fibers, not all available for the various disciplines. The fibercomp (white) has good power and control, k-max and woodcomp (k-max covered with a maple type look) have a good ball control, the graphite has power and accuracy. |

|

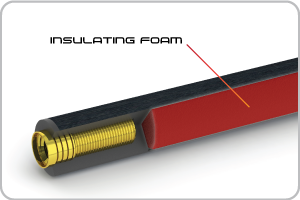

2DF - DOUBLE DENSITY FOAM In order to improve the balance and acoustic, in all laminated shafts close to the joint area, we created a long hole filled with a special foam. This material compensates density, absorbs vibrations and improves the balance. |

|

FIBER LONGONI WARRANTY In spite of wooden shafts, those in fiber are indeformable and resistant to the humidity.For the correct cleaning we recommend the RED TOUCH by longoni cloth that does not need any chemical products. To restore the satin effect of the shafts, we recommend the "NO BLUE POLISH" by longoni product and ABRADO MICRO SANDING PAPERS KIT. The longoni fiber shafts are covered by a guarantee of 24 months by manufacturing defects |

|

MADE WITH THE WORLD CHAMPIONS

Players of the Longoni team have an important role in the development of our shafts because it’s thanks to the skills of the best talents all over the world that we can create excellent shafts. All our models have been tested and approved by our champions in order to ensure the maximum results and satisfaction to our customers. The results speak for themselves: with our shafts the most important worldclass titles have been taken. |

|

MADE IN ITALY: YESTERDAY, TODAY AND TOMORROW

All Longoni shafts, including the laminated ones, are entirely and uniquely produced in Italy in the factory based in Mariano Comense with techniques and machineries developed by us. The processing cycle of each shaft lasts at least 24 months: from when you cut the board to when it reaches the billiard tables around the world. The choice to continue completely producing in Italy was dictated by the desire to have a product different from all the other ones in terms of quality and technology, always under a strict control of our staff. |

|

FIBER SHAFTS: PRECISION AND TRACEABILITY

All Fiber shafts are univocally numbered to trace production date. Each shaft is also labelled to report product specification including code, name, diameter and exact weight .The label, beyond showing these data, is a further guarantee of authenticity. Before labelling, each shaft is individually checked on a test desk to avoid warpage and other defects. To help reporting correct weight and diameter, we use a precision digital scale connected to the system and a laser micrometer.

|

IMPORTANT NOTICE

The company reserves the right to apply modifications or changes to the product without any obligation of previous notice.

L'azienda si riserva il diritto di applicare modifiche e cambiamenti al prodotto senza obbligo alcuno di preavviso.

The company reserves the right to apply modifications or changes to the product without any obligation of previous notice.

L'azienda si riserva il diritto di applicare modifiche e cambiamenti al prodotto senza obbligo alcuno di preavviso.