|

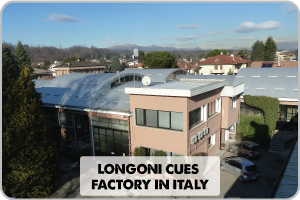

All Longoni cues are produced entirely in Italy in our workshop of Mariano Comense, in the province of Como. For the production of the cues we use woods and several materials from all over the world.

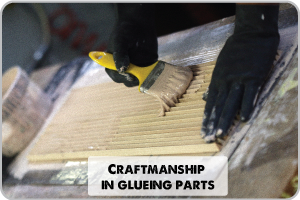

The whole production process takes place under the supervision of the Longoni family.

The Longoni company, based in Mariano Comense, founded over 80 years ago, nowadays is dealing exclusively with the production of billiard cues, billiard lamps and some specific accessories; till 30 years ago, in the same premises, also billiard tables were produced.

Visiting the production factory is possible, only with previous agreements taken by mail (This email address is being protected from spambots. You need JavaScript enabled to view it.) and upon acceptance of the Longoni family.

Tutte le stecche Longoni sono prodotte interamente in Italia, nello stabilimento di Mariano Comense in provincia di Como, utilizzando le nostre maestranze. Per la costruzione delle stecche si usano legni di tutto il mondo e diverse componentistiche Italiane; alcuni materiali ad alto contenuto tecnologico e componenti possono provenire da altri stati della comunità Europea.

Tutta la lavorazione avviene sotto la costante supervisione della famiglia Longoni .

La ditta Longoni di Mariano Comense , fondata oltre 80 anni fa, oggi si occupa unicamente della produzione delle stecche da biliardo, lampadari da biliardo ed alcuni accessori specifici: fino a 30 anni fa , nello stesso stabile si producevano anche i tavoli da biliardo.

La visita alla sede produttiva è possibile, concordandola per tempo con la direzione, scrivendo via mail a This email address is being protected from spambots. You need JavaScript enabled to view it. e previo accettazione della famiglia Longoni.

|